PFAS in Products The Need for Testing to Ensure Consumer Confidence

From pet food to steak, from dental floss to winter jackets, and even everyday items like lipstick and fishing tackle, countless products that consumers rely on may contain potentially harmful substances. While many people use these items without giving much thought to their chemical composition, growing public awareness about the presence of “forever chemicals”—scientifically known as Per- and Polyfluoroalkyl Substancesis prompting consumers to scrutinize their purchases more closely. Companies, too, are taking a proactive stance, recognizing the urgency of regulatory compliance and consumer demand for safer, PFAS-free products. To meet these expectations, businesses are now conducting thorough evaluations of their supply chains, ensuring that every component used in their manufacturing processes aligns with safety and environmental standards.

The Need for Comprehensive PFAS Testing

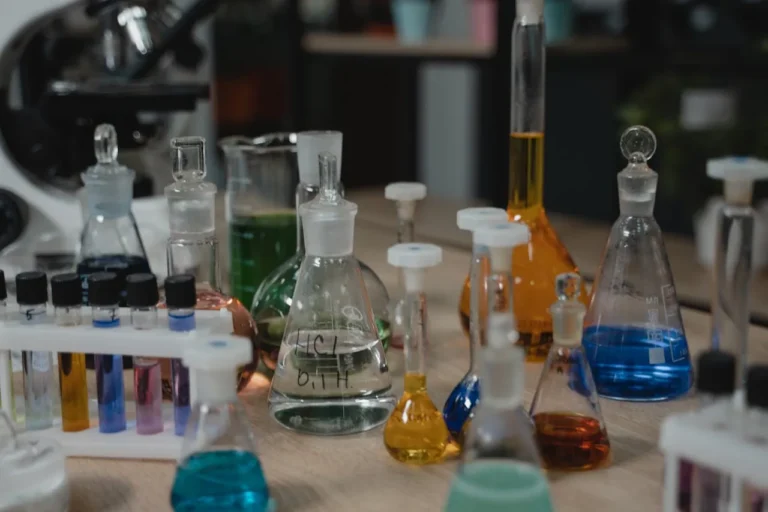

Addressing the PFAS challenge requires more than just identifying these substances in products—it involves a complete understanding of their presence from raw materials to the final product. That’s where Battelle, the world’s largest independent nonprofit research and development organization, plays a crucial role. compounds, first developed in the 1940s, number in the thousands and exhibit remarkable durability and resistance to degradation. While these properties make PFAS useful in a variety of industrial and consumer applications, certain compounds pose significant risks to human health and the environment. Identifying and mitigating these risks demands advanced scientific expertise, extensive testing, and innovative remediation strategies.

Battelle has made significant investments in research and technology to develop advanced PFAS testing capabilities and comprehensive vulnerability assessments. These initiatives allow companies to fully grasp their risk exposure and take the necessary steps to minimize it. Beyond detection, Battelle has been at the forefront of remediation. The organization has pioneered the Annihilator, a groundbreaking technology designed to completely destroy unwanted PFAS compounds found in industrial wastewater, landfill leachate, and firefighting foams. This innovation has led to the creation of Revive Environmental, a company dedicated to deploying this technology in real-world applications, helping to eliminate these persistent contaminants at their source.

A Holistic Approach to PFAS Risk Management

“We are not just testing for PFAS; we are helping companies understand their entire landscape, from supply chain to final product,” said Amy Dindal, Business Line Director at Battelle. “Our goal is to provide data that empowers companies to make informed decisions about their products and practices.”

Battelle’s comprehensive approach to risk management spans multiple industries, supporting businesses in identifying safer alternatives to PFAS-containing materials. By leveraging cutting-edge research and technology, Battelle assists clients in developing sustainable solutions that align with evolving regulatory requirements and consumer expectations.

Key Battelle Initiatives in PFAS Testing and Remediation

1. Expansion of Testing Capabilities

Battelle has significantly increased its capacity to analyze content in a wide range of products. The growing demand for testing services has led to a surge in inquiries from companies seeking to evaluate items such as food, personal protective equipment, textiles, and more. By employing tailored analytical approaches, Battelle ensures that each product undergoes rigorous testing, providing businesses with precise and reliable data on PFAS presence.

2. Comprehensive Risk Mitigation Strategies

Beyond mere detection, Battelle offers in-depth risk assessments to help companies understand where their vulnerabilities lie and how to address them effectively. This proactive approach enables businesses to take preventive measures, reduce exposure risks, and implement strategic mitigation plans. By integrating detailed risk evaluations with customized solutions, Battelle provides a full suite of services that goes beyond basic testing.

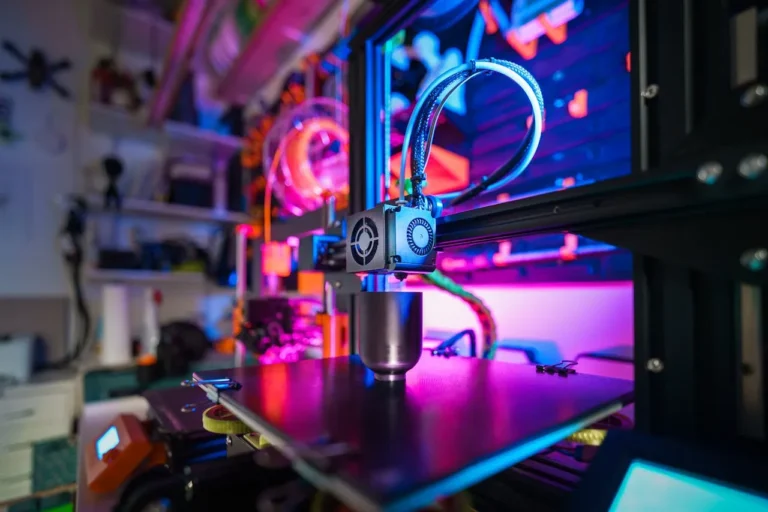

3. Development of Innovative Techniques and Technologies

As a leader in scientific innovation, Battelle continues to refine its methodologies for extracting and analyzing PFAS compounds from various materials. With decades of experience in chemical analysis and environmental research, Battelle remains at the forefront of PFAS detection and remediation. By continuously improving its techniques, the organization helps businesses adapt to regulatory changes and adopt best practices for minimizing PFAS contamination.

About Battelle

Every day, the dedicated scientists and researchers at Battelle apply their expertise in science and technology to tackle some of the world’s most pressing challenges. With operations spanning major technology centers and national laboratories worldwide, Battelle conducts cutting-edge research and development, designs and manufactures critical products, and delivers essential services for both government and commercial clients. Since its founding in 1929, Battelle has remained headquartered in Columbus, Ohio, serving a broad spectrum of industries, including national security, health and life sciences, energy, and environmental sustainability.

Through its pioneering work in PFAS testing and remediation, Battelle continues to play a vital role in helping companies navigate the complexities of management, ensuring safer products, a cleaner environment, and greater consumer confidence in the years to come.