Protolabs Expands Capabilities from Prototyping to Full-Service Production

Protolabs, a leading provider of digital manufacturing services, has significantly expanded its capabilities with the introduction of full-service production. This evolution is designed to support companies at every stage of their product life cycle—from early-stage prototyping and pre-production to large-scale manufacturing and end-of-life product support. By adding full-service production, now offers an integrated solution that provides improved pricing options for large part orders, enhanced quality control, and specific industry certifications critical to the manufacturing process. This expansion continues to uphold reputation for low-volume, quick-turn prototyping services, which remain a cornerstone of their business.

“The marriage of speed and automation to quality control, cost efficiency, and advanced manufacturing is a union unseen in the manufacturing industry until now,” stated Protolabs’ leadership, highlighting how the integration of these elements provides customers with a unique manufacturing experience.

As part of this expansion, Protolabs is also evolving its customer experience. In addition to offering immediate online access to instant quoting, the company now enables customers to directly connect with a team of production experts. This personalized support is designed to help manage entire projects, from complex orders to final production. Customers will benefit from assistance with quoting, file uploads, and navigating orders that include complex bills of materials (BoM) and strategic sourcing from both Protolabs and its trusted network partners. The company’s operations specialists will also assist with logistics fulfillment, while application engineers collaborate with customers to optimize CAD models and reduce overall costs.

Protolabs’ President and CEO, Rob Bodor, explained, “It’s a deeper partnership with our customers—product developers, engineers, buyers, and procurement teams—to ensure full production support from start to finish. We are now truly a single manufacturing resource for companies around the world.”

The company has also reorganized its business structure to enhance customer relationships. Bodor shared that Protolabs’ regional organizations are now focused entirely on ensuring the best customer engagement and experience. Additionally, a global operations team is responsible for seamlessly fulfilling customer part orders, unifying the company’s operations to deliver a comprehensive and efficient service.

Protolabs’ transformation, while adding full-service production, still maintains its core focus on speed and automation, which have been essential to the company’s success since its founding 25 years ago. Luca Mazzei, Protolabs’ Strategic Growth Officer, remarked, “Rapid prototyping driven by automation and technology-enabled processes will always be at the core of who Protolabs is as a company. But as the market has changed, Protolabs is also changing to better meet the evolving needs of our customers. Our expansion into full-service production represents a much more comprehensive way to serve our customers from start to finish.”

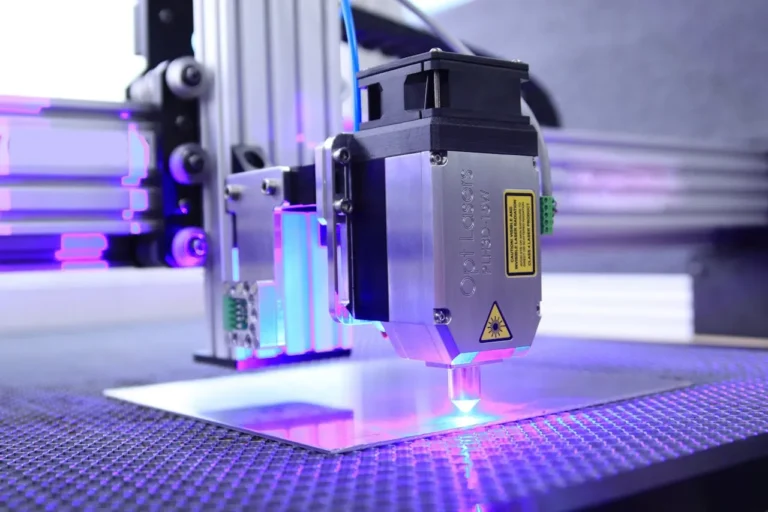

Protolabs’ expanded services aim to meet the growing demands of its customer base by offering an even broader array of capabilities. Through its flagship service lines and manufacturing network, Protolabs can now provide high-volume manufacturing with lower piece-part pricing. High-requirement molding, along with verification and validation processes, will better support industries like medical devices, which require rigorous quality assurance and certification. Additionally, the company’s expertise in advanced polymers and metals for 3D printing helps sectors like aerospace innovate at new levels.

Mazzei emphasized the significance of this expansion: “The marriage of speed and automation to quality control, cost efficiency, and advanced manufacturing is a union unseen in the manufacturing industry until now. Our customers have asked for these combined benefits for years, so we’re excited that we are able to bring this to them—from prototyping to production—and every step along the way.”

Protolabs is revolutionizing the manufacturing process with its fully integrated digital service, making it the fastest and most comprehensive solution in the world for low-volume parts production. Through its digital factories and network of highly vetted manufacturing partners, Protolabs can provide product developers, engineers, and supply chain teams with a one-stop source for all their manufacturing needs—from prototyping to production.

About Protolabs:

Protolabs is the fastest and most comprehensive digital manufacturing service in the world, specializing in the production of low-volume parts in days. The company’s digital factories are designed to help customers quickly prototype and produce parts, while Protolabs Network unlocks advanced capabilities and volume pricing through its trusted network of manufacturing partners. The result is a single manufacturing source that provides complete support for product developers, engineers, and supply chain teams globally.