“In today’s linear economy, products are manufactured, used, disposed of, and recycled in a manner that is not sustainable. This is particularly evident with plastic products, which are often not recognized as valuable resources at the end of their lifecycle. The linear approach contributes significantly to climate change, resource depletion, and environmental pollution. Addressing these challenges requires a shift towards circular design, a crucial yet sometimes overlooked aspect.

Design plays a pivotal role in facilitating circularity, even though it may not always be associated directly with the chemical industry or the concept of the circular economy. It presents a significant opportunity for providers of sustainable and high-performance materials, such as Covestro, to leverage their expertise.

“The design phase has a profound impact on a product’s environmental footprint: from material selection and repairability to ensuring a long and productive lifecycle that ends with recyclability. Therefore, the importance of design cannot be overstated in our journey towards achieving full circularity,” explains Dr. Christopher Stillings, Head of Color & Design at Covestro’s Business Entity Engineering Plastics. “As experts in materials early in the value chain, Covestro is well-positioned to collaborate with designers to integrate circular design principles into product development effectively.”

Driving Change

There is a growing momentum towards adopting circular design principles, driven in part by increasingly stringent regulations. For instance, the EU is advancing regulations that mandate environmentally friendly product designs, emphasizing reusability, repairability, upgradability, and recyclability. Similarly, discussions are ongoing in other regulatory bodies, such as the USA’s Department of Energy, which is promoting recyclability through design as part of its ‘Strategy for Plastics Innovation’.

Covestro’s Contributions

Covestro is actively contributing to advancing circular design through several key initiatives:

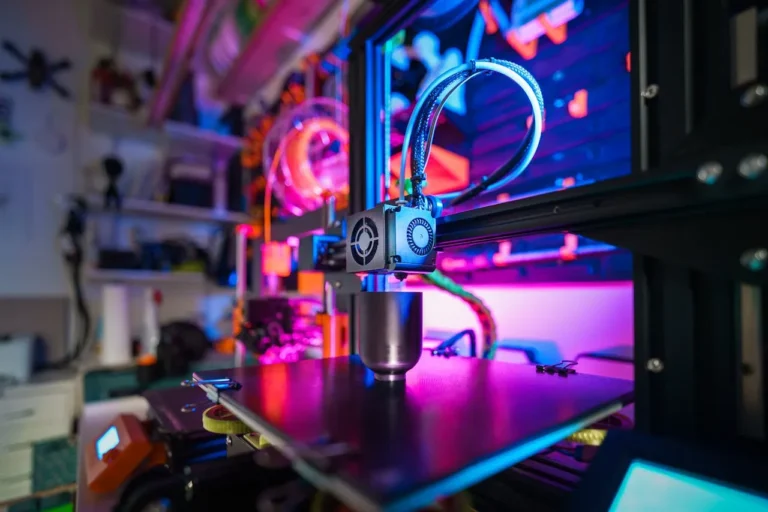

Dematerialization: For example, Covestro recently introduced the IMAGIO® CQ digital sampling tool to streamline sampling processes digitally.

Design for longevity: Leveraging its expertise as a provider of high-performance materials for products in automotive, construction, and cold chain sectors, designed to last for decades.

Modular design: Facilitating ease of disassembly and recycling of product components.

Use of circular raw materials: Introducing materials with low emission footprints, enhancing the circularity of end products from the outset.

Covestro has been a pioneer in addressing circular design principles for decades, drawing on its extensive experience and expertise. The K67, a plastic car showcased at the K-fair in 1967, stands as a testament to Covestro’s early commitment to innovative and sustainable design.

About Covestro:

Covestro is a global leader in manufacturing high-quality polymer materials and components. Through its innovative products, processes, and solutions, Covestro enhances sustainability and improves quality of life across various industries. The company serves customers worldwide in critical sectors including mobility, construction, electronics, sports, telecommunications, healthcare, and the chemical industry itself.”