CleanJoule’s SpaceSAF Fuels Breakthrough Rotating Detonation Rocket Test with Venus Aerospace

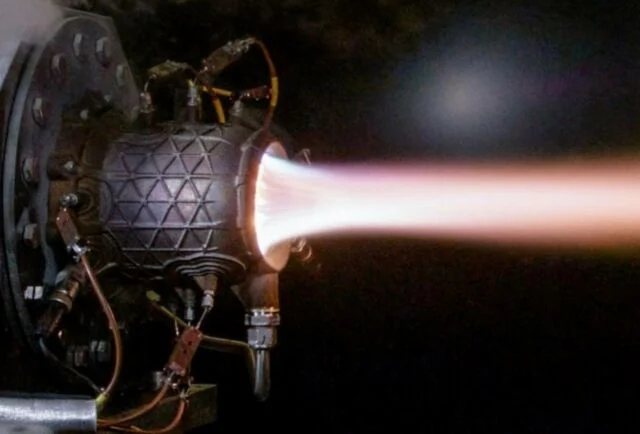

In a pioneering demonstration that signals the future of space propulsion, CleanJoule’s advanced bio-based rocket fuel—SpaceSAF—was successfully used in a Rotating Detonation Rocket Engine (RDRE) developed by Venus Aerospace. The test, conducted at the Houston-based RDRE testing facility, marks the first time that a drop-in sustainable rocket fuel has powered detonation-based engine technology—validating SpaceSAF’s compatibility with high-performance propulsion systems and opening new opportunities for sustainable space missions.

This historic event symbolizes a major leap forward in clean propulsion, offering both improved performance and reduced emissions. Dr. Mukund Karanjikar, CEO and founder of CleanJoule, emphasized the significance of the milestone:

“Without affordable, domestically-produced alternative fuels, the financial and environmental costs of space missions become unsustainable.

The successful detonation of an RDRE utilizing SpaceSAF proves that alternative fuels can deliver for both performance and emissions needs in commercial and defense applications.”

What Is SpaceSAF? A Drop-In Fuel with Performance Benefits

SpaceSAF is a breakthrough liquid bio-derived rocket fuel designed to replace traditional petroleum-derived fuels like RP-1 and RP-2. Developed to be a seamless “drop-in” alternative, SpaceSAF requires minimal—or no—modification to existing engines, pipelines, or ground support equipment.

Key advantages of SpaceSAF include:

- Increased mission capability: Higher energy density per unit mass enhances payload capacity and range.

- Environmental benefits: Derived from sustainable feedstocks and formulated to emit fewer greenhouse gases.

- Tactical flexibility: Compatible with a range of rocket engine architectures, including next-gen detonation systems.

This successful RDRE test underscores SpaceSAF’s ability to perform under extreme pressure and temperature swings typical in detonation cycles.

Rotating Detonation Rocket Engines: A Paradigm Shift

Traditional rocket engines operate on controlled, intermittent combustion. In contrast, Rotating Detonation Rocket Engines (RDREs) use continuous detonation waves spinning in a chamber—an approach that boosts thermodynamic efficiency, improves specific impulse, and reduces hardware complexity.

RDREs offer intriguing advantages:

- Higher efficiency: The detonation cycle’s rapid, near-constant combustion process converts more fuel energy into thrust.

- Reduced part count: Simplified engine design with fewer moving components offers reliability and easier manufacturing.

- Compact form factor: Smaller engines with higher thrust-to-weight ratio benefit mass-sensitive launch platforms.

However, RDREs place more extreme demands on fuel chemistry. This test demonstrated that SpaceSAF maintains stability and performance even under these challenging conditions.

The Test: CleanJoule + Venus Aerospace Collaboration

The proof-of-concept ground test took place at Venus Aerospace’s Houston-based RDRE test site. Engineers installed SpaceSAF in a flight-prototype RDRE and executed a controlled detonation sequence. Data collected on thrust performance, combustion stability, emissions, and chamber integrity met or exceeded expectations for RP-1/RP-2 — affirming SpaceSAF’s readiness for high-performance missions.

A spokesperson for Venus Aerospace explained:

“This test helps advance an important conversation in aerospace: how to pair next-gen propulsion with alternative fuels that don’t compromise on performance.

CleanJoule’s work on high-performance, low-emissions fuels contributes meaningfully to an evolving space and defense ecosystem, and we’re pleased to see their product perform under real operational conditions.”

Why This Matters: Scaling Clean Propulsion

The implications of this milestone are substantial:

1. Environmental Sustainability

The rapidly expanding launch sector—satellite constellations, space tourism, Mars missions—drives up CO₂ emissions from rocket propellants. SpaceSAF offers a route to cleaner flights that meet climate goals and regulatory standards.

2. Economic Advantage

Increased specific impulse translates to greater payload mass or mission range at the same fuel volume—lowering cost-per-kilogram, optimizing mission planning, and boosting competitiveness.

3. Defense and National Security

Military space missions often demand frequent, high-performance launches. A domestically-produced, secure fuel source also mitigates geopolitical risks linked to petroleum supply chains.

4. Infrastructure Compatibility

As a drop-in fuel, SpaceSAF avoids expensive retrofits: existing engines, fueling lines, and safety protocols can be reused without major redesign.

CleanJoule: Innovation in Rocket Fuel

CleanJoule is a U.S.-based cleantech startup that specializes in renewable hydrocarbon fuels and chemicals. Using a patented biological fermentation and catalytic conversion process, CleanJoule produces molecules nearly identical to their petroleum counterparts—but from sustainable feedstocks like renewable natural gas and agricultural residue.

The company’s mission includes:

- Enhancing the sustainability of high-performance fuels while retaining energy characteristics.

- Providing secure domestic supply, reducing dependence on conventional oil imports.

- Specializing in dual-use fuels, serving both commercial space ventures and defense applications.

In addition to SpaceSAF, CleanJoule produces Solid Sustainable Rocket Fuel (SSRF). This solid rocket counterpart offers superior energy density and high-performance propellant tailored for tactical and space launch applications.

Solid Rocket Fuel and Dual-Use Strategy

The same molecular platform that fuels SpaceSAF also forms the basis for CleanJoule SSRF. SSRF enhances the performance of solid rocket motors—offering increased specific energy and more controllable burn profiles.

Solid-fuel rockets are commonly used in:

- Defense systems: tactical missiles, interceptor vehicles, and reusable upper stages.

- Space boosters: first-stage ignition rockets for spacecraft and planetary vehicles.

CleanJoule’s dual delivery—liquid SpaceSAF and solid SSRF—grants flexibility to mission designers, enabling fuel alignment with desired launch profiles and operational needs.

A Fast-Emerging Space Ecosystem

The successful RDRE test aligns with the growing ecosystem of:

- Low-cost satellite deployment: constellations with hundreds to thousands of spacecraft are launching each year.

- Commercial space tourism: companies seek greener propulsion to satisfy regulators and the public.

- Deep-space exploration: missions to Mars, the Moon, and beyond increasingly require innovative propulsion fuels.

- Defense readiness: national agencies are prioritizing secure and clean fuel sources for responsive space systems.

As launches increase—both in frequency and scale—the necessity for low-emission, high-performance fuels will only grow more urgent.

Performance, Emissions, Cost: The Rocket Trilemma Solved?

CleanJoule’s success suggests SpaceSAF may break the classic “rocket trilemma”: high performance, low emissions, and affordability — all in one package.

- Performance: Proven stable operation in RDREs designed for ultra-high extraction efficiency.

- Emissions: Renewably derived fuel cuts lifecycle CO₂ footprint dramatically.

- Affordability: Domestic production and existing handling infrastructure keep costs competitive with conventional RP-1.

As CleanJoule scales production, it could offer substitute fuels at near-parity in price, unlocking widespread adoption.