Mitsubishi Chemical Group’s Advanced Aerospace Materials Enable Lunar Rover YAOKI’s Historic Mission

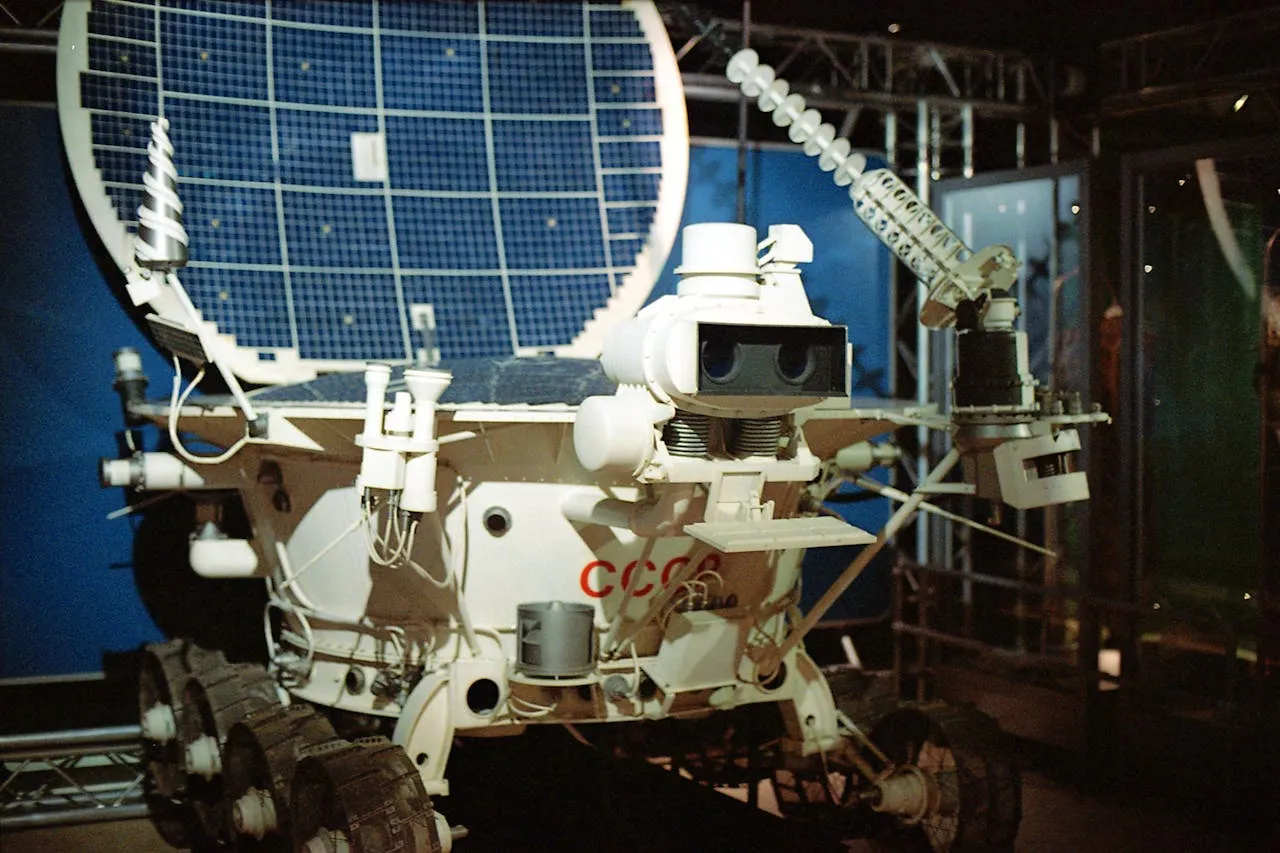

Japan, the lunar rover YAOKI, crafted using specialized aerospace materials from the Mitsubishi Chemical Group (MCG Group), successfully reached the moon and transmitted images of its surface back to Earth. Developed by Dymon Co., Ltd., a venture company specializing in robotics and space development, YAOKI represents Japan’s first private-sector lunar rover. This achievement highlights the increasing role of the private sector in space exploration, supported by cutting-edge technologies and materials provided by companies like MCG Group.

A Historic Achievement for Japan’s Private Sector

YAOKI’s success marked a significant milestone for Japan’s space industry. As the first Japanese private sector lunar rover to reach the moon, it symbolized a key advancement in the nation’s space exploration efforts. The rover was part of a private-sector initiative that saw collaboration between Dymon Co., Ltd. and the MCG Group. Despite facing unexpected challenges during its landing, YAOKI’s mission was successful in capturing valuable images of the moon’s surface and transmitting them back to Earth, making it a key milestone in lunar exploration.

The Unexpected Landing Setback

While YAOKI’s mission was largely successful, it was not without its hurdles. YAOKI was transported to the moon aboard a lunar lander developed by U.S.-based Intuitive Machines. Unfortunately, the lander toppled onto its side upon landing, preventing YAOKI from being deployed and moving across the lunar surface as initially planned. Despite this issue, the rover was still able to capture images of the moon and send the data back to Earth.

Additionally, engineers on Earth confirmed that all of YAOKI’s intended functions were operational. This included the rotation of its wheels, even though the rover was unable to physically traverse the lunar surface. The data collected about YAOKI from launch to the end of its mission helped verify that the rover’s technology was working as designed.

Expanding the Private Space Sector

The involvement of private companies in space exploration has been on the rise globally, with the market for space-related industries expected to reach a staggering 140 trillion yen by 2040. The MCG Group, through its participation in the YAOKI project, is now looking to expand further into the space sector. Starting in fiscal 2025, the Group will launch additional aerospace projects aimed at developing new materials for lunar exploration and expanding its innovative graphite sheet business. These new initiatives are designed to help the MCG Group leverage its expertise in advanced materials to support the ongoing development of space exploration technologies.

Source: The Ministry of Economy, Trade and Industry, Japan (March 2024) [in Japanese]. Link to document

Mitsubishi Chemical Group’s Critical Role in YAOKI’s Success

MCG Group’s contribution to the YAOKI project was vital to its success, with advanced aerospace materials playing a central role in the rover’s performance. The Group’s proprietary materials helped achieve key goals for the rover, such as weight reduction, shock resistance, and durability in the harsh conditions of space. The following four technologies were particularly significant in making YAOKI operational on the moon:

1. Structural Design for the Slider: Compliant Mechanism

MCG Group’s advanced design technologies were employed in the rover’s structural slider using super-engineering plastics. The complex shape of the rover’s slider was created through one-piece injection molding, a technique that allowed the formation of a shape that is impossible with traditional molding methods. This design contributed to the rover’s enhanced durability and operational capability under extreme conditions.

Reference: Press release on Compliant Mechanism Design for Lunar Rover YAOKI (April 12, 2024) Link to Press Release

2. Body & Deployer: Cyanate Ester-Based CFRP

To enhance the rover’s shock resistance and thermal performance, MCG Group utilized cyanate ester-based carbon fiber reinforced plastic (CFRP) in the body and deployer, the rover’s transport case. CFRP is known for its high thermal resistance and strength, making it ideal for the harsh lunar environment. Replacing conventional aluminum with CFRP increased the rover’s shock resistance five-fold while also reducing its weight by 30%.

3. Tires: Polyamide-Imide (PAI) Super Engineering Plastic

YAOKI’s tires were made from polyamide-imide (PAI), a super-engineering plastic that is highly resistant to heat, cold, abrasion, and shocks. PAI’s exceptional properties allowed the rover’s tires to endure extreme temperatures up to 250°C, ensuring they would continue to function even under the harsh conditions of the lunar surface. This material also provided the necessary durability to withstand the shocks caused by any falls or impacts.

4. Lenses: Anti-Regolith Coating

Lunar regolith, the fine dust covering the moon’s surface, can be a significant challenge for imaging equipment due to its sharp, microscopic particles. To prevent this regolith from sticking to the rover’s lenses, MCG Group developed a special coating agent. This coating prevented the regolith from adhering to the lenses, ensuring that YAOKI’s cameras would remain clear and functional throughout the mission.

Looking Ahead: MCG Group’s Future in Space Exploration

Building on the success of YAOKI, the MCG Group plans to continue its involvement in space exploration and expand its contributions to the industry. In addition to the projects related to lunar exploration, MCG is also pursuing innovations in materials that could support future missions to the moon and beyond. These ongoing initiatives will play a significant role in the Group’s goal of developing highly competitive technologies that can address the unique challenges of space exploration.

As the private space sector grows, the MCG Group is poised to remain at the forefront of technological advancements, helping to shape the future of space missions and exploration. Through its cutting-edge materials and engineering expertise, MCG is making important strides toward supporting the next generation of space technologies.

Conclusion: A New Era of Private Space Exploration

The successful mission of YAOKI represents a major milestone for Japan’s private sector in space exploration. Despite the challenges faced during the landing phase, YAOKI’s ability to capture and transmit images from the moon and confirm the operation of all its systems demonstrates the success of private sector innovation in space. With the continued support of advanced aerospace materials from MCG Group, the future of space exploration looks increasingly promising.

This rewritten article expands on the key technological innovations used in the development of YAOKI, highlights the challenges and successes of its mission, and discusses the MCG Group’s future plans in the space sector. Let me know if you need further adjustments or additions!